info@jsktraders.com

info@jsktraders.com

info@jsktraders.com

info@jsktraders.com

Product

CuCo2Be—C17500 (CDA 175) Cobalt Beryllium Copper is primarily utilized in the industry applications that require most highly thermal or electrical conductivity, which features a cobalt alloying addition (2.40-2.70%).

Online consultation

Online consultation

Product Introduction

Typical Application for C17500 Cobalt Beryllium Copper Alloys

Electrical Industry: Fuse Clips, Switch Parts, Relay parts, Connectors, Spring Connectors

Fasteners: Washers, Fasteners

Industrial: Springs, Seam Welding Dies, Resistance Welding Equipment, Resistance and Spot Welding Tips, Tooling for Plastic Moulds, Die–Casting Plunger Tips.

Available Sizes

Custom Diameter & Sizes, Random Mill lengths

Available Products (forms)

Round bars, Round wires, Round tube,

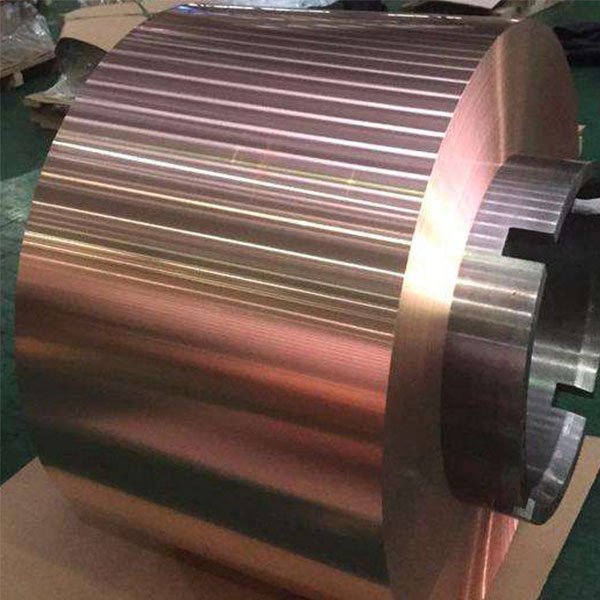

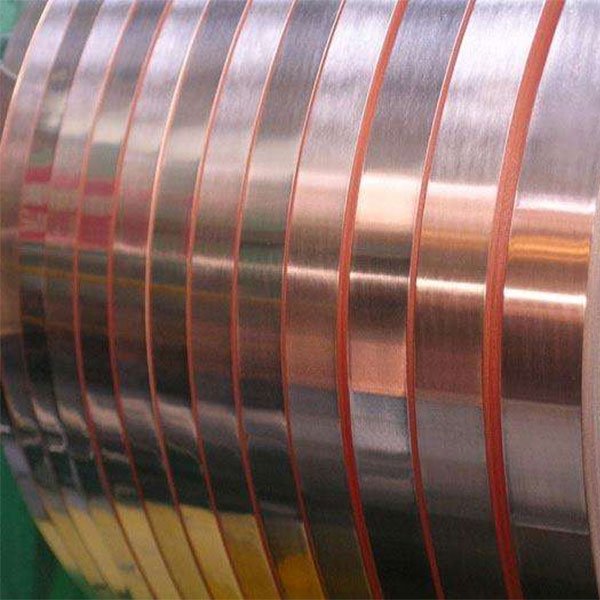

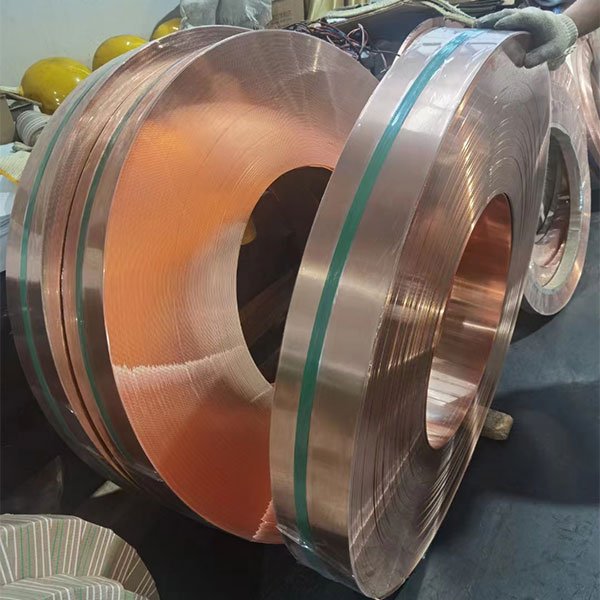

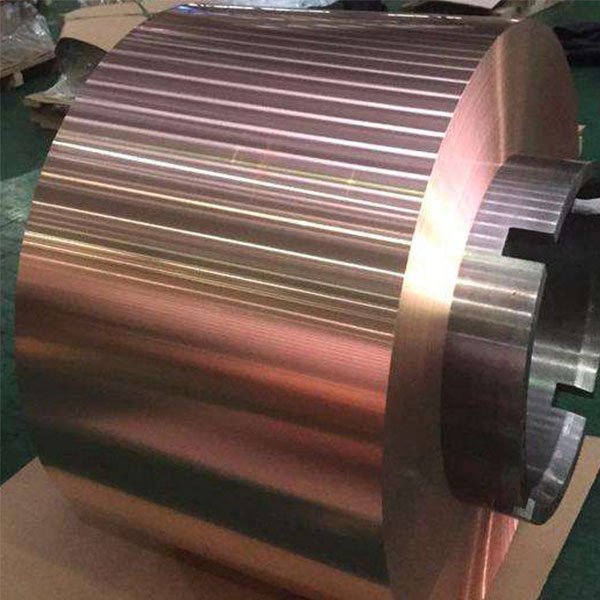

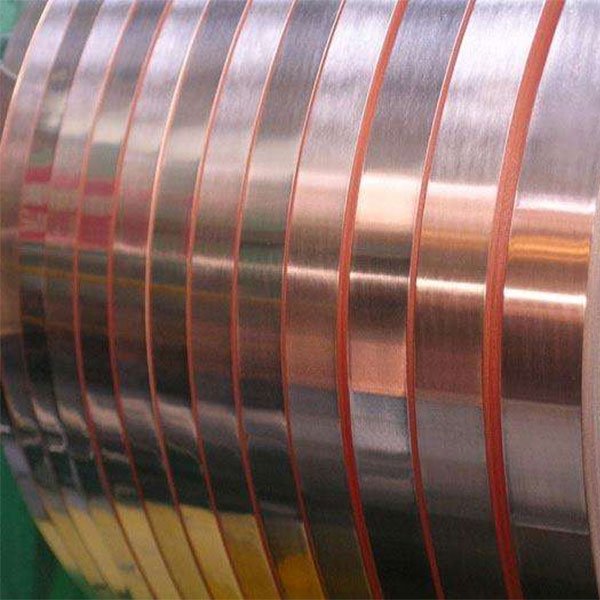

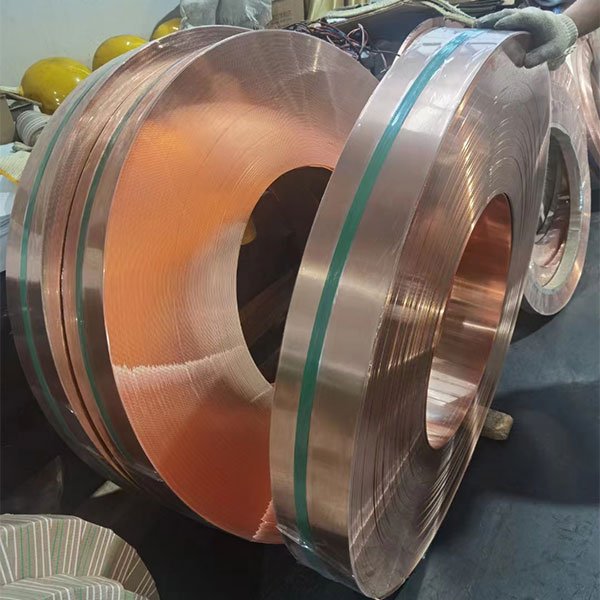

Flat bars, Square bars, Rectangular bars, Hexagon bars, Plates, Sheets, Coils

Custom shapes are available upon request.

Chemical Composition

Be: 0.40-0.70%

Co: 2.40-2.70%

Cu: Balance

Note: Copper plus additions equal 99.5% minimum.

Typical Physical Properties

Density (g/cm3): 8.83

Density before age hardening (g/cm3): 8.75

Elastic Modulus (kg/mm2 (103)): 14.10

Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C): 18 x 10-6

Thermal Conductivity (cal/(cm-s-°C)): 0.48

Melting Range (°C): 1000-1070

Note:

1). the units are based upon Metric.

2). the typical physical properties apply to age hardened products.

International Specification

Rods/Bars/Tubes: ASTM B441, SAE J461,463; RWMA Class 3

Strips: ASTM B534

Sheets: ASTM B534

Wires: ASTM B441

Plates: ASTM B534, SAE J461,463; RWMA Class 3

European Standards:CuCo2Be, DIN 2.1285; CW104C to EN

Note:

ASTM: American Society for Testing and Materials

SAE: Society of Automotive Engineers

AMS:Aerospace Materials Specification (Published by SAE)

RWMA:Resistance Welder Manufacturers' Association

Note: Unless otherwise specified, material will be produced to ASTM.

Mechanical Properties:The Mechanical Properties will be available on request from customers.

Most Commonly Temper Used

Rods/Bars/Tubes: A(TB00),H(TD04),AT(TF00),HT(TH04)

Strips: A(TB00),1/4 H(TD01),1/2 H(TD02),H(TD04)

Sheets: A(TB00),1/4 H(TD01),1/2 H(TD02),H(TD04),AT(TF00)

Wires: A(TB00),1/4 H(TD01),1/2 H(TD02),3/4H(TD03),H(TD04)

Plates: AT(TF00),HT(TH04)

Return

Return