info@jsktraders.com

info@jsktraders.com

info@jsktraders.com

info@jsktraders.com

Product

Brass is obtained from the alloy of copper Cu + zinc Zn and it has different qualities/characteristics depending on the proportion of each metal involved. Meanwhile, other materials may be involved in its composition, leading to combinations adapted to different requirements. The malleability of brass thus depends on the temperature at which the substances are mixed and the proportion in which they are added.

Online consultation

Online consultation

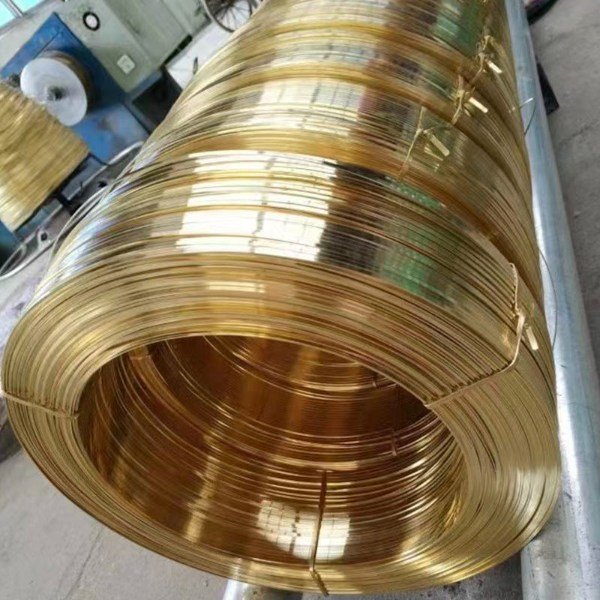

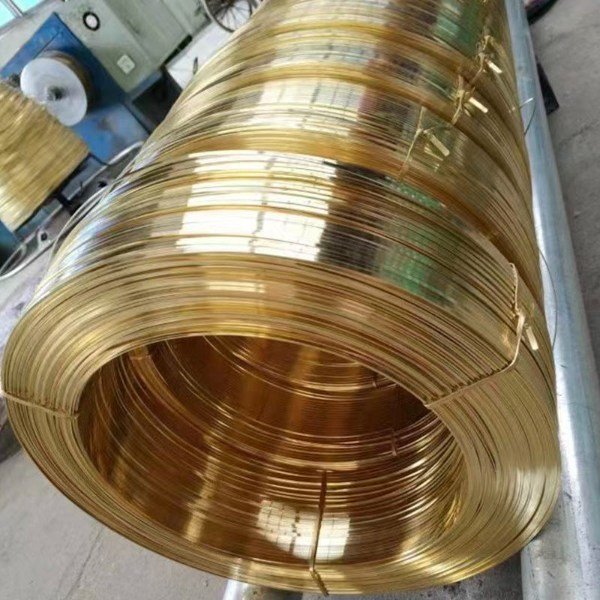

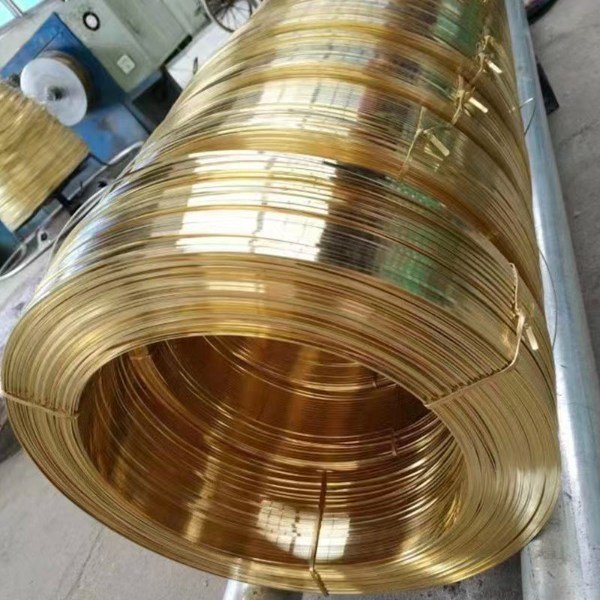

Product Introduction

Specifications:

• Dimensions:

Diameter: 0.02mm-25mm

*Customized size needs to be confirmed with us

• Classification: Cold heading wire (CHQ wire), spring wire, welding wire, hydrogen wire, bright wire, half-soft wire, soft wire, cold-forging wire, electrolytic wire as well as special-shaped wires.

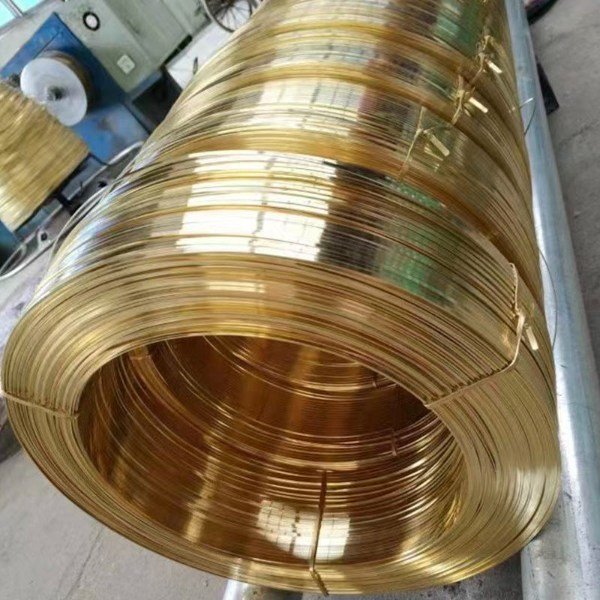

Features:

It has greater machinability and ductility than other alloys.

Solidity against wear.

It has high electrical conductivity.

It has excellent properties for welding.

Brass is a metal that can easily be recycled. Its waste can be separated with ease and re-cast as many times as necessary.

It does not alter at extreme temperatures, between -100ºC and 200ºC and it does not fade in light.

It has high resistance to corrosion and rust, even in saline conditions.

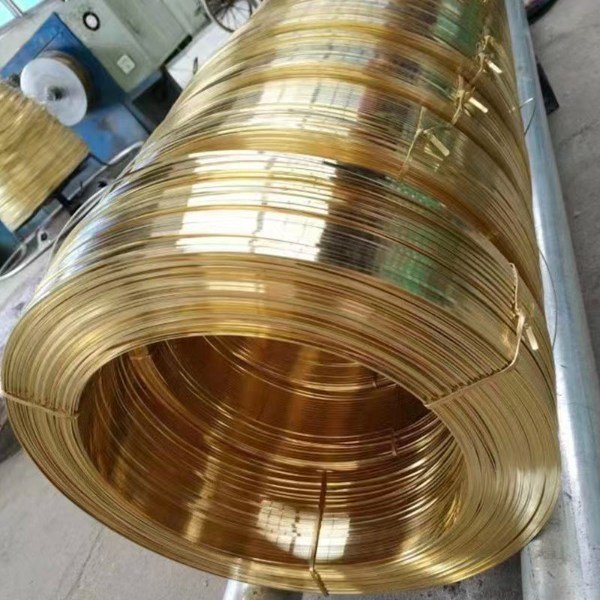

Applications:

Main features of brass wire: Brass wire has strong wear resistance. It has high strength, high hardness and strong chemical corrosion resistance. There are cutting mechanical properties are also more prominent. The brass wire is drawn into a seamless copper tube, which is soft and wear-resistant. Brass wire seamless tubes can be used in heat exchangers and condensers, cryogenic piping, subsea transport pipes. Manufacture of sheets, bars, rods, pipes, casting parts, etc. Containing 62% to 68% copper, strong plasticity, used to manufacture pressure-resistant equipment, etc.

Aluminum in brass wire can improve the strength and hardness of brass, and improve the corrosion resistance in the atmosphere. Brass wire is used to manufacture corrosion-resistant parts

Main Grades

Classification | United Kingdom (BS) | Germany (DIN) | Japan (JIS) | EN (symbol) | EN (Number) | China | America (ASTM) |

Copper | C102 | ECu-58 | C1100 | Cu-ETP | CW004A | T2 | C11000 |

Oxygen-free Copper | C103 | OF-Cu | C1020 | Cu-OF | CW008A | TU1 | C10200 |

Phosphorized Copper | C106 | SW-Cu | C1201 | Cu-DLP | CW023A | TP1 | C12000 |

SF-Cu | C12100 | 121 | |||||

C106 | 2.0090/2.0076 | C12200 | 122 | ||||

Silver containing Copper | C101 | CuAg0.1 | C1271 | TAg0.08 | C13000 | ||

Cadmium Copper | C108 | CuCd1 | CuCd1 | CuCd1 | CW131C | TCd1 | C16200 |

Berryllium Copper | C112 | CuCo2Be | CuCo2Be | CuCo2Be | CW104C | TBe0.6-2.5 | C17600 |

Brass | CZ125 | CuZn5 | C2100 | CuZn5 | CW500L | H96 | C21000 |

CZ101 | CuZn10 | 2.023 | CuZn10 | CW501L | CuZn10 | C22000 | 220 |

CZ102 | CuZn15 | 2.024 | CuZn15 | CW502L | CuZn15 | C23000 | 230 |

CZ103 | CuZn20 | 2.025 | CuZn20 | CW503L | CuZn20 | C24000 | 240 |

CZ106 | CuZn30 | 2.0265 | CuZn30 | CW505L | CuZn30 | C26000 | 260 |

CZ126 | C26100 | ||||||

CuZn33 | 2.028 | CuZn33 | CuZn33 | C26200 | 262 | ||

CZ107 | CuZn36 | 2.0335 | CuZn33 | CW506L | C26800 | 268 | |

CuZn36 | CuZn36 | C27000 | 270 | ||||

CZ108 | CuZn37 | 2.0321 | CuZn36 | C27400 | 274 | ||

CuZn37 | CW508L | C27200 | 272 | ||||

CuZn40 | 2.036 | CuZn40 | CW617N | C28000 | 280 | ||

CZ109 | CuZn40 | 2.036 | CuZn40 | CW617N | C28000 | 280 | |

DCB1 | G-CuZn37Al1 | 2.0595.02 | CuZn37Al1-C | CuZn40Y40 | C85800 | 858 | |

G-CuZn25Al5 | 2.0598.03 | CuZn25Al5Mn4Fe3-C | CuZn19Al6Y20 | C86200 | 862 | ||

HTB1 | G-CuZn34Al2 | G-CuZn34Al2 | CuZn32Al2Mn2Fe1-C | CuZn30AlFeMn | C86400 | 864 | |

CZ118 | CuZn36Pb1.5 | 2.0331 | CuZn35Pb1 | CW625N | CuZn35Pb2 | C34000 | 340 |

Leaded Brass | CZ119 | CuZn36pb1.5 | C3560 | CuZn36pb1.5 | HPb63-3 | C34500 | |

CZ124 | CuZn36pb3 | CuZn36pb3 | C34700 | 347 | |||

CuZn37pb0.5 | 2.0332 | CuZn37pb0.5 | C34900 | 349 | |||

CZ120 | C36000 | 360 | |||||

CZ123 | CuZn39Pb0.5 | CuZn39Pb0.5 | CuZn37Pb1 | CuZn39Pb0.8 | C36500 | 365 | |

CuZn32pb2 | CuZn32pb2 | C35300 | 353 | ||||

CZ129 | CuZn38Pb1.5 | CuZn38Pb1.5 | CuZn38Pb1 | C37000 | 370 | ||

Z120 | CuZn39Pb2 | 2.038 | CuZn39Pb2 | CuZn39Pb2 | C37700 | 377 | |

CZ122 | CuZn39pb3 | 2.038 | CuZn39pb3 | CuZn39pb3 | C37800 | 378 | |

CZ121 | 2.0401 | C38000 | 380 | ||||

CZ121/3 | CuZn39Pb3 | 2.0401 | CuZn39Pb3 | CuZn39Pb3 | C38500 | 385 | |

Tin Brass | CuZn38Sn1 | C4640 | CuZn38Sn1As | C46400 | |||

Phosphor Bronze | PB101 | CuSn4 | C5102 | CuSn4 | CW451K | QSn5-0.2 | C51100 |

CT1 | G-CuSn10 | 2.1050.01 | CuSn10-C | CuSn8 | C90700 | 907 | |

PB2 | G-CuSn12 | 2.1052.04 | CuSn12-C | CuSn12-C | C91700 | 917 | |

PB1 | CuSn10P | CuSn10P | CuSn11P-C | CuSn10P | |||

Aluminium Bronze | CuAl5As | CuAl5As | C60800 | ||||

CA104 | CuAl10Ni5Fe4 | 2.0966 | CuAl10Ni5Fe4 | CuAl9Ni5Fe3 | C63000 | 630 | |

Silicon Resd Brass | G-CuZn15Si4 | SzBC2 | CuZn16Si4-C | C87500 | |||

SCB3 | G-CuZn33Pb | 2.0290.01 | CuZn33Pb2-C | CuZn33PbY20 | |||

Leaded Tin Bronze | LB2 | G-CuPb10Sn | LBC3 | CuSn10Pb10-C | C93700 |

Tolerances

Our Brasssteel Wire is manufactured in compliance with the main international specifications.Tighter tolerances are available upon request.Custom tempers are available upon request.

Packaging

All of our Brasssteel Wire are packaged as per international standard to prevent any possible damage or loss. By default, we will use thick woven plastic bag to bundle the finished pipes together in batches.

For some special Wires that are vulnerable to dirt, scratches, stress or rough handling, we will suggest wooden case for protection. Kindly note, wooden case can incur extra cost, not only its own cost, but also the increased freight cost, which is especially true for air transportation. For enhanced customer experience, we also provide dedicated package as per your special requirements.

Return

Return