info@jsktraders.com

info@jsktraders.com

info@jsktraders.com

info@jsktraders.com

Product

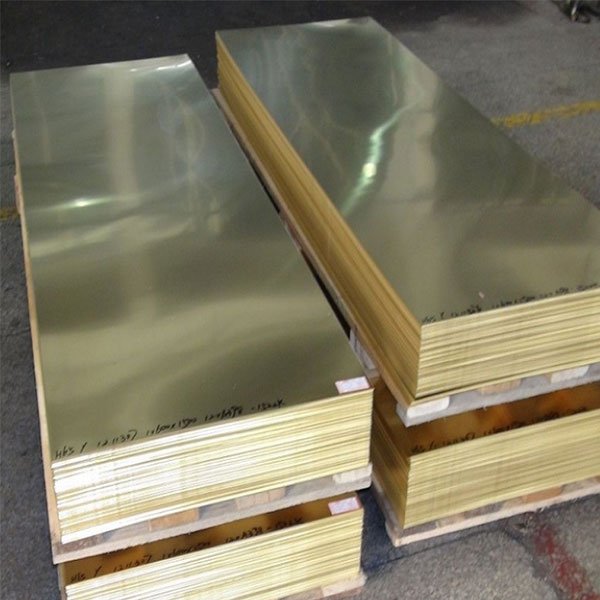

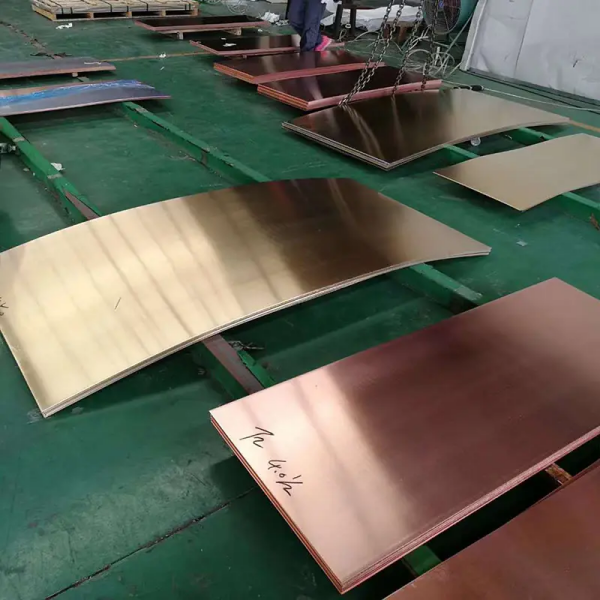

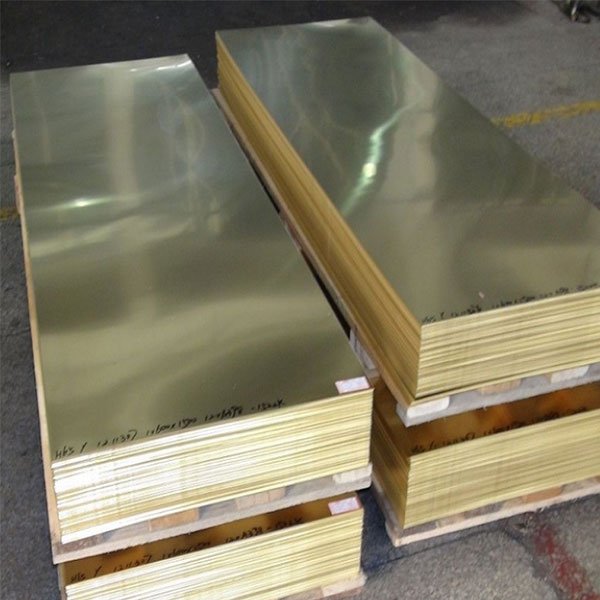

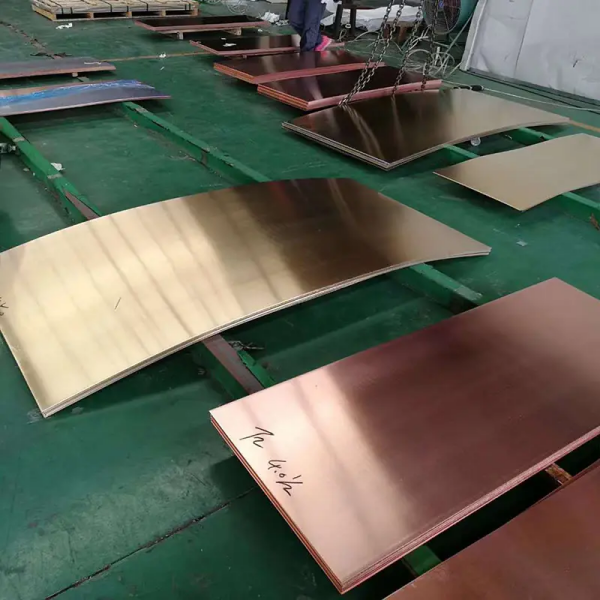

Brass is a 60:40 copper zinc alloy to which about 1% of tin has been added to improve the corrosion resistance, particularly to dezincification. The allov is a two phase alpha-beta brass. hence has reasonablv high strength with lower ductility than the singlephase 70:30 or alpha brass.

Online consultation

Online consultation

Product Introduction

CHEMICAL COMPOSITION

Elements | Min(%) | Max(%) |

Cu | 59.00 | 62.00 |

Pb | - | 0.20 |

Sn | 0.50 | 1.00 |

Fe | - | 0.10 |

Total Others | - | 0.50 |

Zn | Remainder | |

MECHANICAL PROPERTIES ACCORDING TO ASTM B371 (AS PER TEMPER HO2)

Range(Inch) | From | To | UTS Min (ksi) | PS Min(ksì) | Elongation Min(%) | Hardness Min(HRB) | Hardness Max(HRB) |

Round(Dia) | 0.059 | 0.500 | 60 | 27 | 22 | ||

0.500 | 1.000 | 60 | 27 | 25 | 60 | 80 | |

1.000 | 2.000 | 58 | 26 | 25 | 55 | 80 | |

2.000 | 2.953 | 54 | 25 | 25 | 55 | 80 | |

Hex(A/F) | 0.118 | 0.500 | 60 | 27 | 22 | ||

0.500 | 1.000 | 60 | 27 | 25 | 60 | 80 | |

1.000 | 2.000 | 58 | 26 | 25 | 55 | 80 | |

2.000 | 2.756 | 54 | 25 | 25 | 55 | 80 | |

Square (A/F) | 0.118 | 0.500 | 60 | 27 | 22 | ||

0.500 | 1.000 | 60 | 27 | 25 | 60 | 80 | |

1.000 | 2.362 | 58 | 26 | 25 | 55 | 80 | |

Rectangle (Thickness) | 0.1181 | 0.500 | 60 | 27 | 22 | ||

0.500 | 1.000 | 60 | 27 | 25 | 60 | 80 | |

1.000 | 1.968 | 58 | 26 | 25 | 55 |

Range(mm) | From | To | UTS Min(MPa) | PS Min(MPa) | Elongation Min(%) | Hardness Min (HRB) | Hardness Max(HRB) |

Round (Dia) | 3 | 12 | 415 | 185 | 22 | ||

12 | 25 | 415 | 185 | 25 | 60 | 80 | |

25 | 50 | 400 | 180 | 25 | 55 | 80 | |

50 | 75 | 370 | 170 | 25 | 55 | 80 | |

Hex(A/F) | 3 | 12 | 415 | 185 | 22 | ||

12 | 25 | 415 | 185 | 25 | 60 | 80 | |

25 | 50 | 400 | 180 | 25 | 55 | 80 | |

50 | 70 | 370 | 170 | 25 | 55 | 80 | |

Square (A/F) | 3 | 12 | 415 | 185 | 22 | ||

12 | 25 | 415 | 185 | 25 | 60 | 80 | |

25 | 50 | 400 | 180 | 25 | 55 | 80 | |

50 | 60 | 370 | 170 | 25 | 55 | 80 | |

Rectangle (Thickness) | 3 | 12 | 415 | 185 | 22 | ||

12 | 25 | 415 | 185 | 25 | 60 | 80 | |

25 | 50 | 400 | 180 | 25 | 55 | 80 |

PHYSICAL PROPERTIES | |

Melting Point -Liquidus°F | 1650 |

Melting Point -Solidus°F | 1630 |

Density lb/cu in.at 68°F | 0.304 |

Specific Gravity | 8.41 |

Electrical Conductivity %IACS at 68°F | 26 |

Thermal Conductivity Btu/ sq ft/ft hr/°F at 68°F | 67 |

Coefficient of Thermal Expansion 68-57210-6 per°F(68-572° | 11.8 |

Specific Heat Capacity Btu/lb /°F at 68°F | 0.09 |

Modulus of Elasticity in Tension ksi | 15000 |

Modulus of Rigidity ksi | 5600 |

FABRICATION PROPERTIES | |

Technique | Suitability |

Soldering | Excellent |

Brazing | Excellent |

Oxyacetylene Welding | Good |

Gas shielded Are Welding | Fair |

Coated Metal Are Welding | Not Recommended |

Spot Weld | Good |

Seam Weld | Fair |

Butt Weld | Good |

Capacity for Being Cold Worked | Fair |

Capacity for Being Hot Formed | Excellent |

Forgeability Rating | 90 |

Machinability Rating | 30 |

Return

Return